Converging the wisdom and strength of all parties, the MFP260-I micro-disturbance four-axis mixing pile drilling machine (DMP method equipment) is a new type jointly developed by SEMW and Shanghai Yuanfeng and other well-known domestic enterprises and institutions. The four-axis mixing pile drilling machine is mainly used to solve the slight unevenness of the pile body, the low level of informatization, the difficulty in controlling the construction quality, the replacement of more soil, the large construction disturbance, and the low efficiency of pile formation during the construction of traditional mixing piles. question. Recently, the equipment has shown its edge in two key projects in the "14th Five-Year Plan" of Shanghai Pudong Zhangjiang Town and Shanghai Pudong Airport, accelerating the first-line infrastructure construction in Pudong New Area.

Pudong Airport South Area Underground Transportation Hub and Supporting Projects。

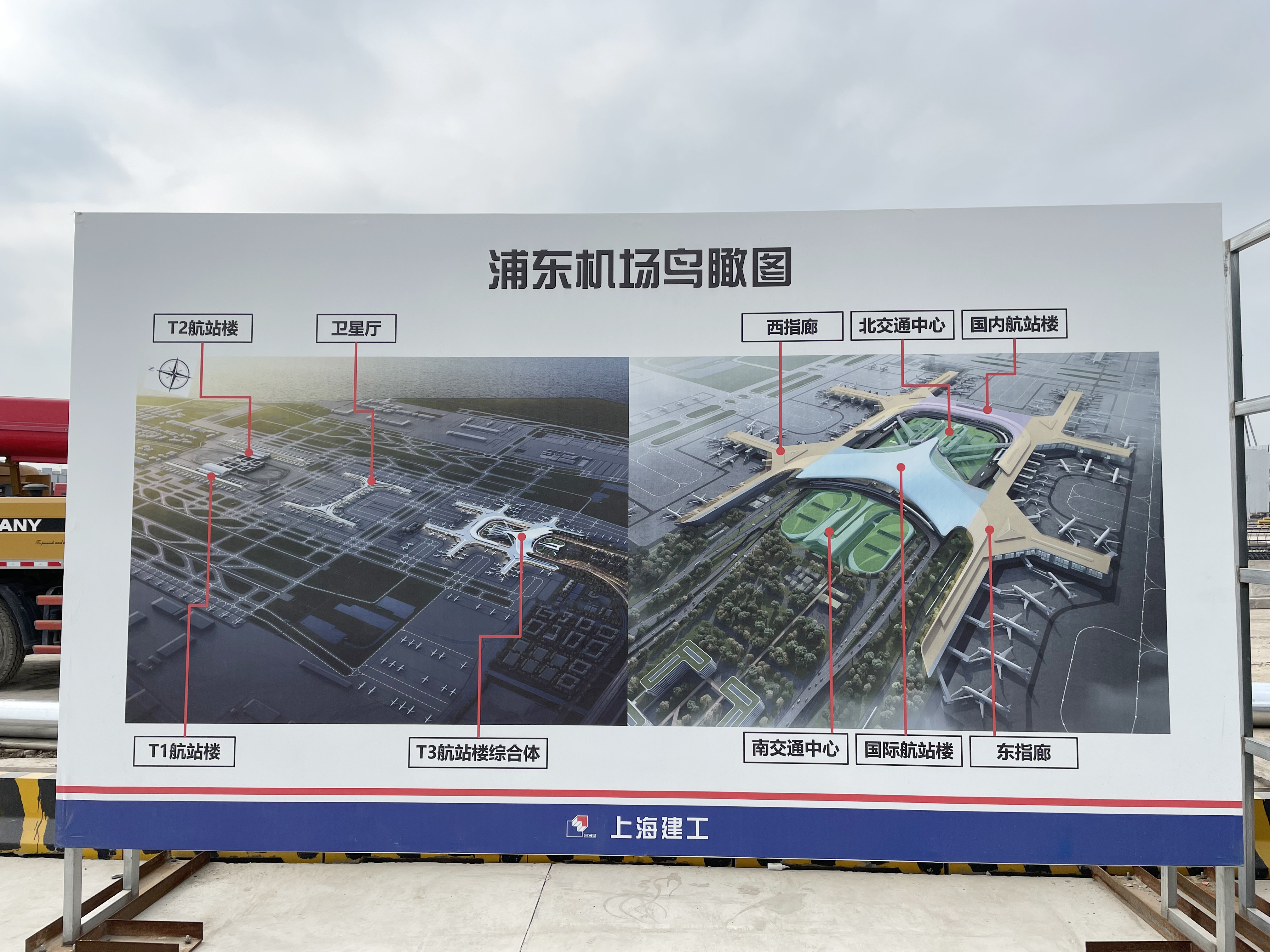

The underground transportation hub and supporting projects in the south area of Pudong Airport are located in Pudong New District, Shanghai, west of Pudong Airport MRT area, east of Feiao Road, south of Pudong Airport Satellite Hall and north of Weichanghe Road. The total investment of the project is 58 billion yuan, the total construction area is 640,000 square meters, and the foundation pit area is nearly 500,000 square meters.

The project is mainly the T3 terminal complex project, which is an integrated building integrating the terminal building, traffic center, north-south parking buildings, municipal ground roads and supporting facilities. According to the planning plan, the terminal building is divided into two main buildings, domestic and international, including Reserved civil engineering structures such as rail transit platforms and station halls, underground parking facilities, and related municipal facilities.

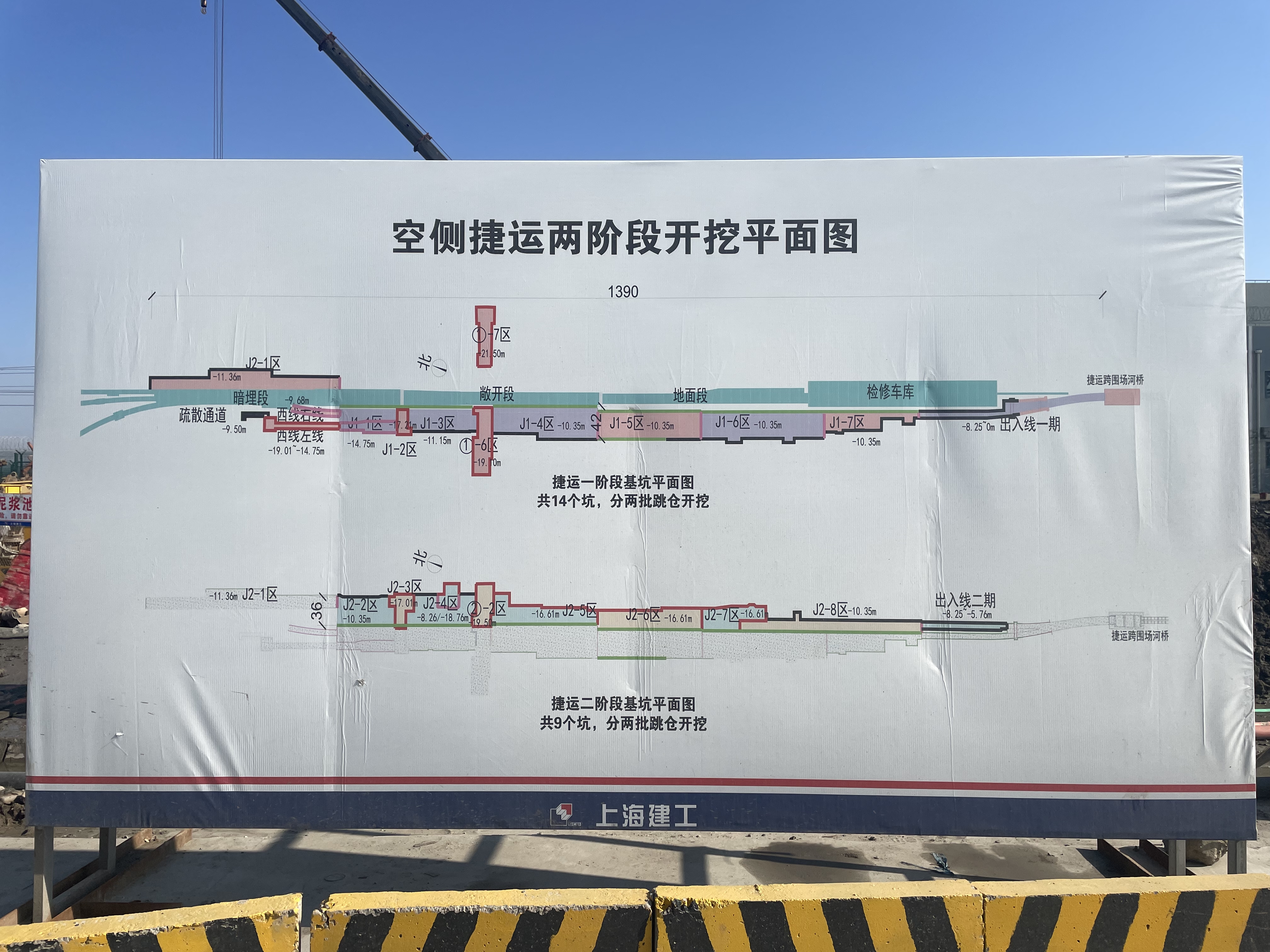

The total TRD construction volume of this project is about 210,000 square meters. At present, more than 10 TRD construction machines of SEMW have been gathered to carry out multi-section water-stop curtain continuous wall operations before excavation of the foundation pit. In order to ensure that the subway line 2 in the airport MRT area Normal operation, 3 meters away from the subway maintenance workshop, designed by the East China Architectural Design Institute and Shanghai Shenyuan Geotechnical Engineering Co., Ltd., double-row micro-disturbance four-axis mixing water-stop piles, and the middle sets of cast-in-place piles to ensure that the foundation does not shift after excavation. The extension of the four-axis mixing pile is 180 meters, the double row is 360 meters, the depth is 19.5 meters, the excavation depth is 10 meters, the cement parameter is 15%, the water-cement ratio is 1:1, and the project requires that the verticality of the water-stop mixing pile is not greater than 1/300 , The wall position deviation is not greater than 50mm, the wall thickness deviation is not greater than 20mm, the wall depth and wall thickness must not have negative deviations, and the equipment makes 10-12 piles within 12 hours, which has extremely high requirements for construction technology and equipment performance.

MFP260-I micro-disturbance four-axis mixing pile drilling machine can effectively reduce the resistance during deep mixing, improve the mixing uniformity of cement and soil and the quality of pile formation. The equipment can not only add cutting blades as needed to prevent clay from sticking to the drill pipe and form mud balls, and reduce disturbance to the formation, but also has a special design of drilling tools and supporting equipment, and the verticality of the pile can be controlled at 1/300. The efficiency is obvious and highly praised by the construction party. the

As the first manufacturer in China to realize a complete set of overall solutions for underground foundation construction, SEMW has made outstanding contributions in many fields of foundation construction. Responsibility and responsibility coexist, quality and innovation coexist. Shanggong produces each product with ingenuity. Serve every customer with thoughtfulness, fully assist the construction of national urban infrastructure, and fully meet the construction needs of customers. SEMW will always be on the road!

MFP260-I micro-disturbance four-axis mixing pile drilling machine (DMP method) introduction:

MFP260-I micro-disturbance four-axis mixing pile drilling machine is a four-axis mixing pile construction equipment combined with air and slurry. The product can complete the construction of four-axis mixing piles combining air and slurry, which can effectively reduce the resistance during deep mixing. Improve the mixing uniformity of cement and soil, so that the pile quality is high. The DMP construction method is a construction method combining air and slurry, mainly to solve the uneven strength of the pile body, low level of informatization, difficult control of construction quality, more soil replacement, large construction disturbance, and pile formation in the construction process of traditional mixing piles. Low efficiency and other problems; this construction method can effectively reduce the resistance during deep mixing, improve the mixing uniformity of cement and soil and the quality of piles. the

product structure:

Application fields:

●As a waterproof retaining wall in the excavation of underground fortifications;

●As a waterproof wall in river reconstruction projects;

●Prevent river water infiltration under the dam;

●Be used as a protective wall when laying pipelines;

●Soft foundation reinforcement. the

Features:

Accurate monitoring, real-time adjustment of slurry and gas pressure, reducing formation disturbance;

●Special drill pipe to open up release channels for slurry and gas pressure;

●Add cutting blades as needed to prevent clay from adhering to the drill pipe and forming mud balls, reducing disturbance to the formation;

●The design of special drilling tools and supporting equipment can improve the uniformity of mixing, and the verticality of the pile can be controlled at 1/300.

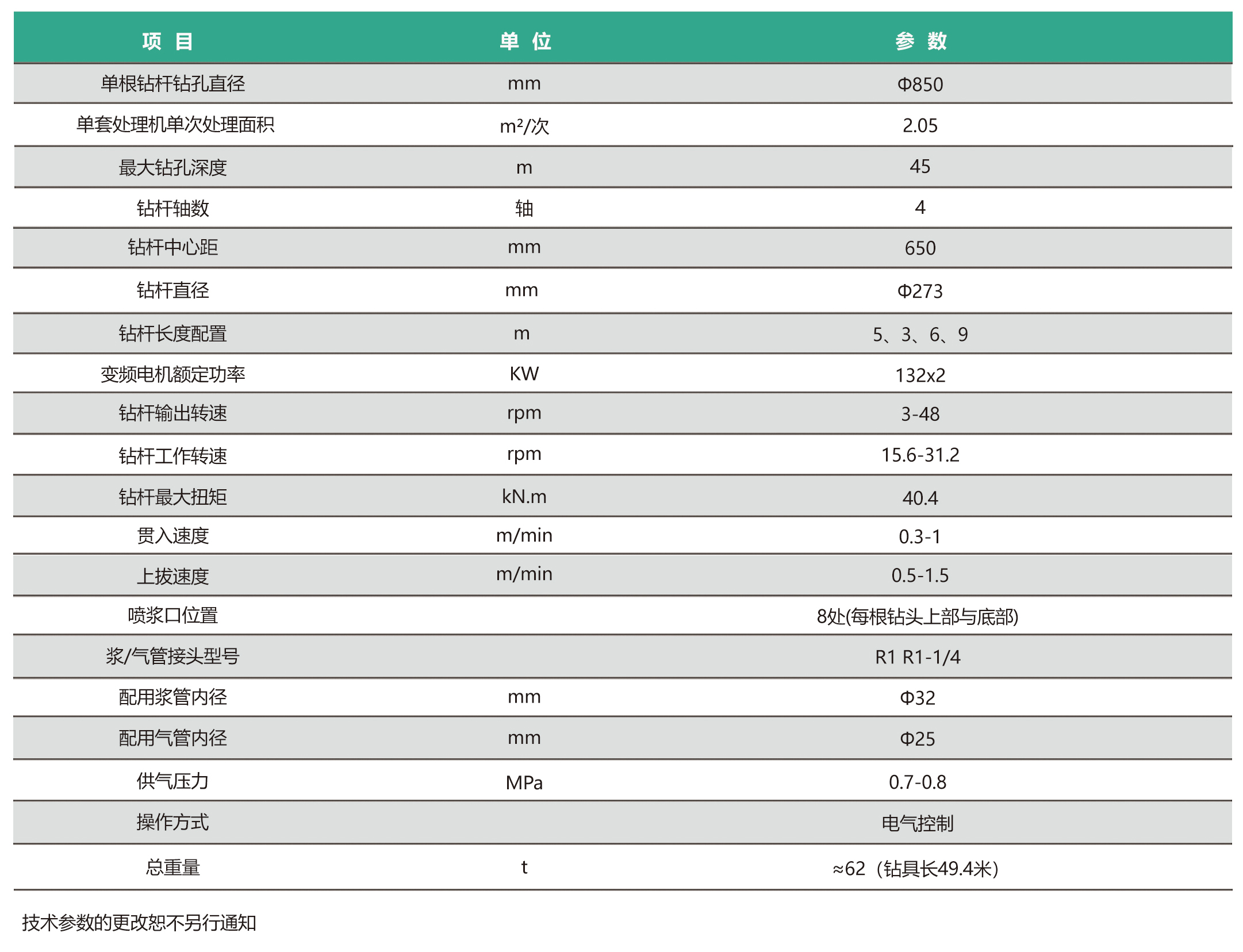

Performance parameters of MFP260-I micro-disturbance four-axis mixing pile drilling machine:

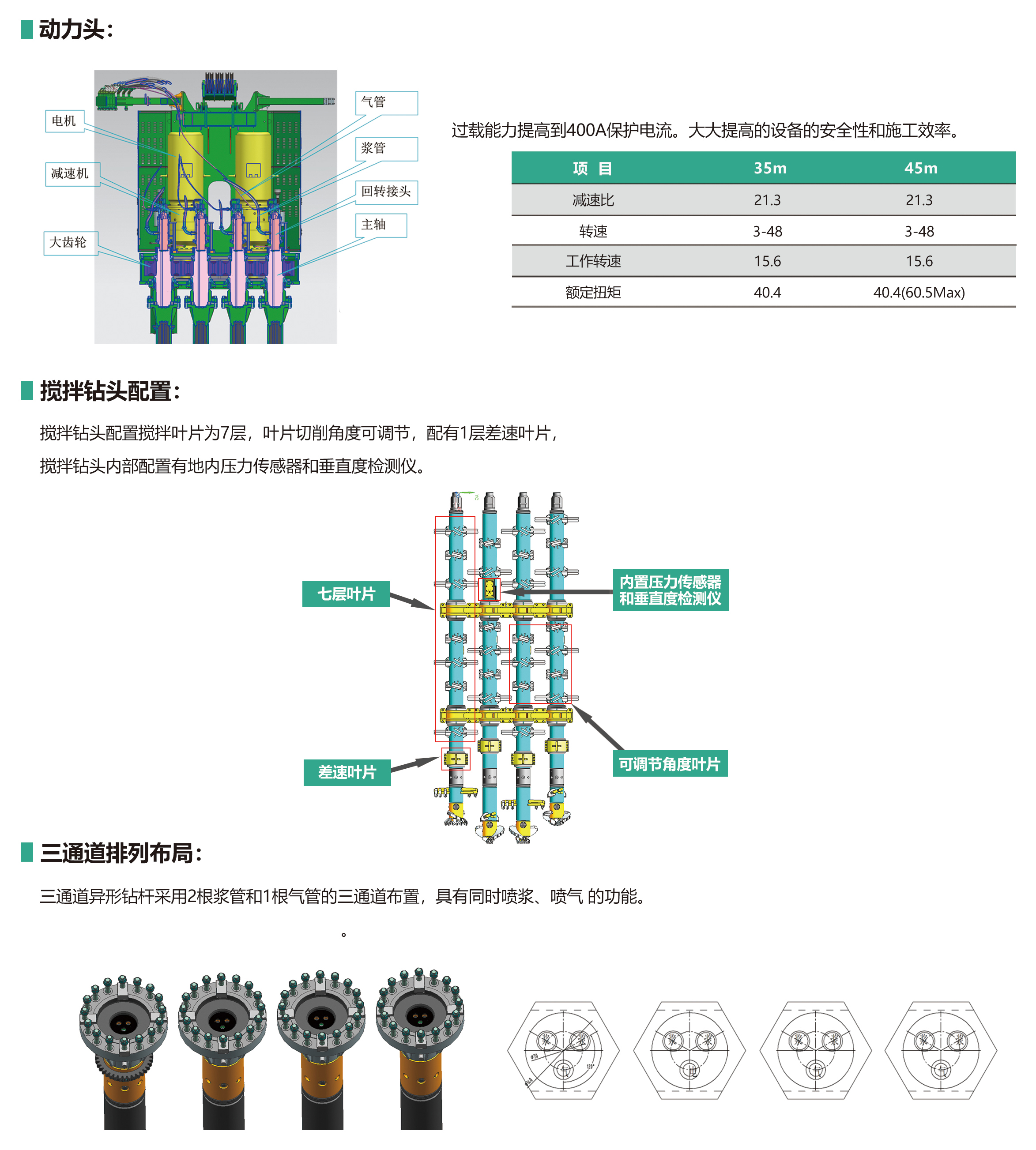

Technical features of key parts:

SEMW, the overall solution expert for foundation construction around you!

For more information about SEMW products and information, please write to us: sales@semw.com

Please contact us

Post time: Jan-06-2023

한국어

한국어