OEM manufacturer Trench Cutting Re-Mixing Deep Wall Method Machine - PIT300 rammed shaft casing oscillators – Engineering Machinery

OEM manufacturer Trench Cutting Re-Mixing Deep Wall Method Machine - PIT300 rammed shaft casing oscillators – Engineering Machinery Detail:

Product Detail

The machine has comprehensive functions, flexible and portable cover all kinds of machine functions at home and abroad, with a variety of speed and torque control, automatic vertical adjustment, tool head force control, remote wire control and other characteristics of convenient operation, no noise, low vibration, superior and reliable performance.

PIT METHOD INTRODUCTION

PIT method is using rammed shaft casing oscillators PIT300, through a special outer casing (steel cylinder) to the ground while shaking and pressing way, it is a vibration free, low noise, energy saving and environmental protection method to construct foundation pit by digging part of retaining steel casing.

Compared with other steel sheet pile supporting projects, it highlights the excellent technology of safety, economy and efficiency

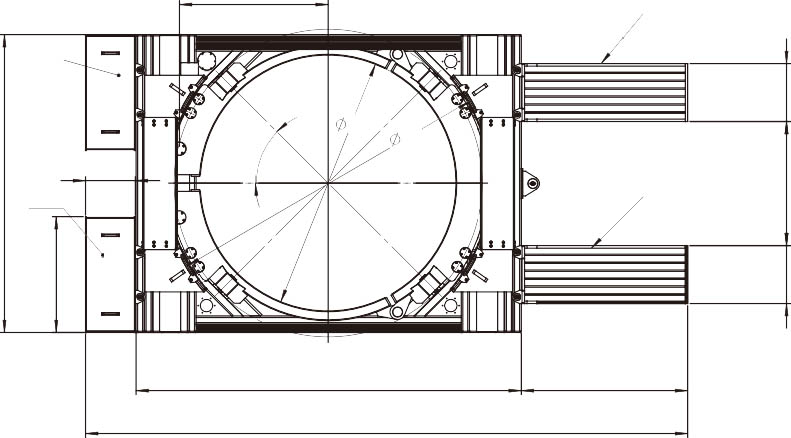

DIMENSION

TECHNICAL SPECIFICATIONS

| Host parameters | ||

| Max. diameter | mm | 3090 |

| Max. pressure | kN | 441 |

| Max. lifting force | kN | 980 |

| Max. oscillating force | kN.m | 1176 |

| Max. oscillating angle | 12° | |

| Pressure cylinder number | pcs | 4 |

| Oscillating cylinder number | pcs | 2 |

| Clamping cylinder number | pcs | 1 |

| Body weight | kg | 8500 |

| lifting stroke | mm | 300 |

| Hydraulic parameters | ||

| Max. pressure | MPa | 20.5 |

| Pump displacement | ml/r | 25 (2 Groups) |

| Motor capacity | kW | 18.5 (2 Groups) |

| Oil tank capacity | L | 450 |

| Dimensions | mm | 1350×1050×1500 |

| Body weight | kg | 1780 |

FEATURES

1. Safe and efficient

All operations are carried out on the ground to effectively ensure personnel safety, no need working in the foundation pit. In the construction process, steel casing can effectively block the soil and protect wall, effectively eliminate the hidden danger of ground collapse and foundation subsidence.Equipment dexterity light weight even can work in the narrow space of the road; Even on the lack of a self-supporting foundation, there is no need for material injection and other auxiliary processes, suitable for different types of foundation.

2. No vibration, low noise

Hydraulic cylinder helps the steel casing pipe press in and pull out, which can achieve no vibration and low noise.

3. Advanced control system & high-precision

Intelligent operating system helps construction personnel quickly grasp the operation mode of equipment.

Advanced control system can ensure the verticality of the steel casing, provide the stable pressure force for different formation, and ensure the high-precision.

APPLICATION

1.Subway foundation, deep foundation pit retaining occluding pile, urban reconstruction pulling pile and removing obstacle pile, railway, port, road bridge, river, lake, high-rise building, hydropower construction bored pile, special purpose bored pile.

2.Full casing can be used when approaching existing buildings, especially suitable for urban operation.

Product detail pictures:

Related Product Guide:

Fast and superior quotations, informed advisers to help you choose the correct merchandise that suits all your requirements, a short generation time, responsible quality control and different services for paying and shipping affairs for OEM manufacturer Trench Cutting Re-Mixing Deep Wall Method Machine - PIT300 rammed shaft casing oscillators – Engineering Machinery, The product will supply to all over the world, such as: Venezuela, Muscat, Hyderabad, Strict quality control is executed in each link of the whole production process.We sincerely hope to establish the friendly and mutual-beneficial cooperation with you. Based on high quality products and perfect pre-sales /after-sales service is our idea, some clients had cooperated with us for more than 5 years.

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!

한국어

한국어