The embankment is 6 meters at its narrowest and 8 meters at its widest

Height 10 meters, slope 21 degrees

How to carry out TRD construction work on such a narrow embankment?

Isn't this just a direct recommendation to quit?

today

let's change perspective

See SEMW’s first pure electric drive TRD-C40E construction machine

Taking on the mission, going on the first expedition

Assisting in the construction of a huge renovation project for my country’s second largest freshwater lake

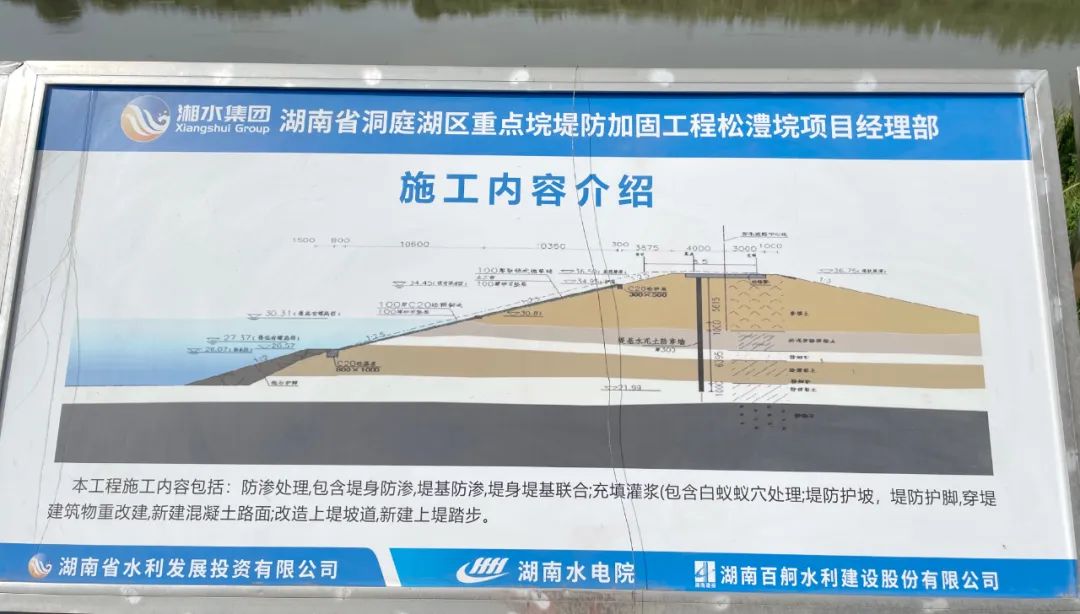

Dongting Lake District Key Embankment and Embankment Reinforcement Project

Steady progress for dam filling!

The first phase of the key embankment reinforcement project in the Dongting Lake District of Hunan Province is one of the 150 major national water conservancy projects. There are 226 large and small embankments in the Dongting Lake District, including 11 nationally recognized key embankments. Since the flood control in 1998, it has been under construction for a long time. Due to the poor soil quality of the embankment body and poor geological conditions of the embankment base, as well as the fact that the flood water level has frequently exceeded the design flood level of the embankment in recent years, the flood control safety of key embankments cannot be guaranteed, and embankment reinforcement construction needs to be carried out.

According to the importance of the protected objects, 6 key embankments including Songli, Anzao, Yuanli, Changchun, Lannihu, and Huarong Mocheng were selected from the 11 key embankments this time for comprehensive reinforcement and management to meet the standards. The project duration is 45 months. , with a total investment of 8.5 billion yuan.

The section participating in the construction bid this time is a first-line flood control embankment of Pinellia. The embankment reinforcement construction is carried out on this embankment with a total length of 88.7km. Due to the extremely narrow width of the dam body, the height difference in the terrain and the fragile ecological environment, the construction is quite difficult. It is large and puts forward higher requirements for construction equipment.

After SWMW's first purely electric-driven TRD-C40E construction machine completed rolling off the production line, it went out for the first time. It went straight to the first-line flood control embankment of Dongting Lake District and carried out the construction of a multi-section water-stop curtain continuous wall with a depth of 32m and a wall thickness of 550mm on a narrow embankment. . At the actual site, the TRD-C40E construction machine became a beautiful sight on the embankment with its excellent practical performance.

The first expedition to fight for a major water conservancy project

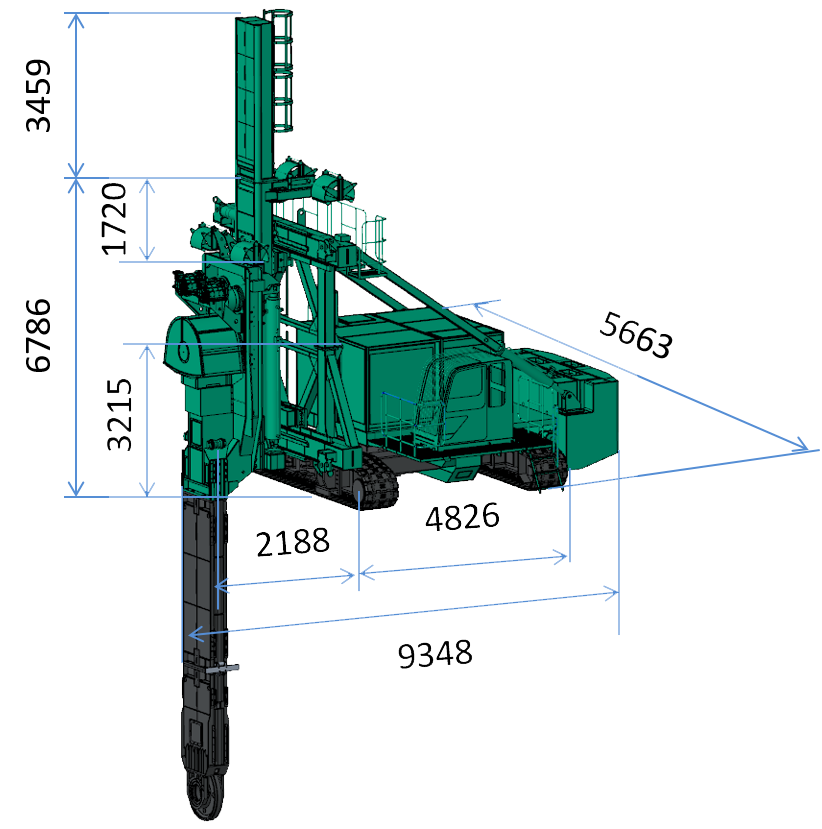

The embankment is 6 meters narrowest, 8 meters wide, 10 meters high, and has a slope of 21 degrees. This narrow construction site alone makes it difficult for many similar TRD construction machines to operate. The TRD-C40E construction machine has a small body size and It has low power consumption and a newly designed pure electric drive crawler chassis, which has stronger maneuverability and higher construction efficiency.

The TRD-C40E construction method machine has a dual power system, a pure electric main power system and a hydraulic auxiliary system (pure electric drive, higher efficiency, energy saving and environmental protection), which can adjust the motor speed and motor torque to cope with different geological requirements. The maximum construction depth of the equipment is 50m, the wall width is 550-900mm, and the net construction height is 6.8m-10m. At the same time, the equipment has an intelligent construction management system, which makes operation and management easier and allows owners to track the construction process and remotely supervise the construction quality.

Master Wang, the on-site operator, lamented: TRD-40E pure electric power is not inferior to diesel engine power at all, but it is far more energy-saving and environmentally friendly than diesel engine power. It only has 3 kWh/m3. The on-site geological layer is mainly silty clay and powder. For sand and pebbles, the cutting speed of the equipment can reach 2m-3m/h. It works nearly 20 hours a day. The equipment does not stop and the failure rate is very low. The staff works in two shifts and the work efficiency is very high. SEMW is a brand I have always trusted. , the product performance this time did not disappoint us!

Attentive service and full guarantee

Due to various reasons such as limited site space, terrain height difference, and fragile ecological environment that needs to be protected, the TRD-C40E construction machine also faces many difficult tests. Although advance preparations have been made on the site before construction, unexpected situations cannot avoid.

To this end, SEMW dispatches a professional service team to be stationed at the project site for a long time, on call 24 hours a day, to respond to service needs at any time, and to ensure safe, efficient and stable project construction.

After the implementation of the key embankment reinforcement project in the Dongting Lake District, the flood control capacity of each key embankment will be effectively improved, greatly reducing the pressure of flood control and flood relief, which will be conducive to promoting high-quality social and economic development, conducive to social stability and unity, and its benefits will penetrate into the social economy and people's lives. all aspects.

With the market demand for water-stop curtain continuous wall construction rising year by year, TRD construction methods and equipment construction methods have been widely used in water conservancy project construction, foundation pit maintenance, subway stations, sealed partitions of pollution sources, bank protection and other purposes. With the TRD The application cases of construction technology in China are gradually increasing, and the superiority of TRD construction will be gradually verified. We firmly believe that TRD construction technology will usher in a gorgeous bloom in the near future.

TRD-C40E construction method machine product advantages:

1. Low headroom all-electric drive

The net construction height is 10m, the minimum height is 6.8m, the width is 5.7m, and the length is 9.5m. The construction area is small; it is fully electric driven, energy-saving, environmentally friendly, and low noise; the maximum construction depth is 50m, and the wall width is 550-900mm.

2. Dual power system

Pure electric main power system: adjustable motor speed and motor torque to cope with different geological requirements; combined with electro-hydraulic auxiliary system to ensure construction flexibility and quality controllability, improve cutting efficiency and reduce energy consumption.

3. Intelligent control

Different construction parameters are set according to different strata to improve construction efficiency while improving equipment reliability; real-time monitoring of equipment status and working status through remote monitoring and camera monitoring; it has the function of operating equipment remotely at close range.

4. Crawler integrated equipment

The transfer is convenient, the transportation, disassembly and assembly are simplified, the overall transportation does not exceed 35t, the length, width and height are not restricted, the transportation width is 3.36m, and the transportation height is 3.215m.

5. Convenient maintenance

The platform space is reasonably laid out, and maintenance space and maintenance channels are reserved.

6. High construction efficiency

The construction efficiency is higher than the SMW construction method, and the construction efficiency at a depth of 40m is close to or exceeds TRD-C50 and similar products on the market.

7. High ability to resist risks

The strength of the lifting structure is optimized, the lifting force reaches 90T*2, and it is equipped with outrigger cylinders to meet risks such as buried drilling at standard depths.

8.New cab design

It adopts an excavator cab with beautiful appearance and reasonable layout; adjustable seats and air-conditioning system make the construction environment more comfortable; multiple display screens are combined to monitor the construction status in real time.

TRD-C50 construction method machine technical parameters:

Post time: Sep-05-2023

한국어

한국어