JB160A Hydraulic Walking Piling Rig

Product Features

HYDRAULIC WALKING PILING RIG

1. MORE EFFECTIVE, STABLE AND DURABLE

The leader, main platform and walking gear are designed for heavy-duty pile driving, to ensure more stable and effective work.

Weight carrier of bigger load bearing.

2. EASY FOR ASSEMBLY AND TRANSPORATION

Modular structure design, easy for assembly and disassembly.

Out triggers of the platform with the rotary pin structure, is driven by cylinder, which saves trouble of disassembly. Can be disassembled and transported by parts, easy for

transportation.

3. ADVANCED ELECTRO-HYDRAULIC CONTROL SYSTEM AND TECHNOLOGY

Both main drum and auxiliary drum are under electro-hydraulic proportional control, available for variable speed control and lock any speed.

Main pump, control valve, pressure gauge, drums are all using domestic and foreign well-known brands.

4. PRACTICAL AND RELIABLE OPERATION MONITORING SYSTEM

Standard leader with goniometer and inductive load angle monitor (optional) provide instant information about batter piling and pulling force, set alarm while in danger. The previous functions can be achieved while the piling rig working with ZLD series agitating auger and sensors (optional).

Deep mixing pile monitor (optional) provides data of pile depth, piling speed, the amount of slurry, and output of the information.

5. COMFORTABLE OPERATION CAB FOR EASY CONTROL

Well insulated operator’s room with five wind shields assures bright, quiet environment with minimum fatigue.

Hydraulic actuated winch control levers allow well performance and easy control.

Space for drill control box, inductive load angle monitor (optional), deep mixing monitor (optional) is reserved in the operator’s room, make the single-driver control easy and reliable.

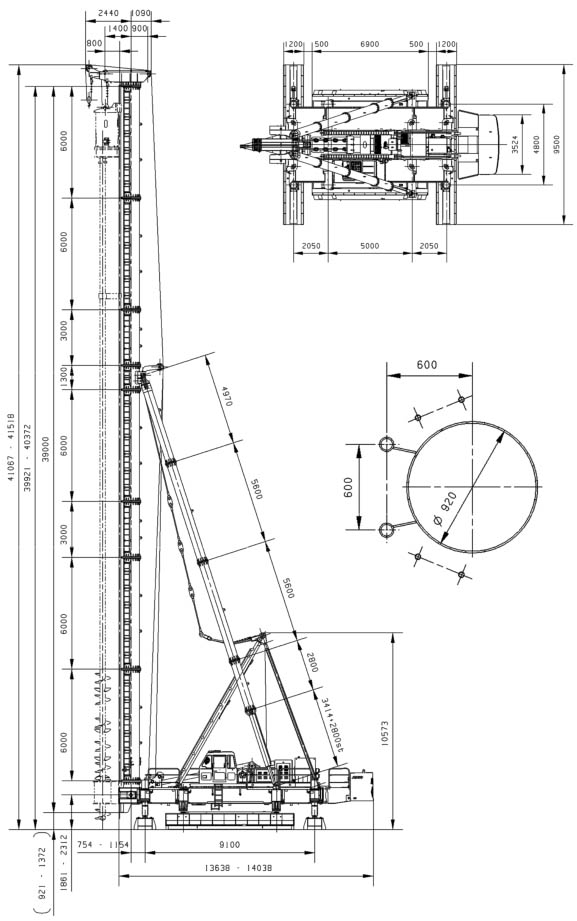

TECHNICAL PERFORMANCE CHARACTERISTICS OF JB160A

1. JB160A is equipped with capacious drums. Standard leader is 39m high (Max.42m), suitable for SMW method.

2. Length of horizontal cylinder reaches up to 3100mm, easy to move while using SMW method. Horizontal stroke of the cylinder reaches up to 400mm, providing more flexibility in construction work.

3. JB160A lifting cylinders ensure a 900mm-lift-height.

4. Unique positioning structure design guarantees a self-erect without help of service crane. JB160A can make 39m height.

5. JB160A was granted complete intellectual property rights and 7 authorized patents, including 2 patents for invention.

Product Model: JB160A

Specifications

| Item | JB160A Hydraulic Walking Piling Rig | |

| Total length of leader (m) | 21~39 | |

| Diameter of leader (mm) | ø920 | |

| Center distance between leader and mounted equipment (mm) | 600×ø101.6 | |

| Leader inclination angle (left to right) (°) | ±1.5 | |

| Backstay stroke (mm) | 2800 | |

| Leader trimming cylinder stroke (mm) | 400 | |

| Max. auger model | ZLD180/85-3-M2-S | |

| Max. diesel hammer model | D160 | |

| Max. leader length (m) | 39 | |

| Max. pulling force (with Max. leader) (KN) | 706.3 | |

| Hydraulic winch (for mounting auger, diesel hammer) | Pulling force of single rope (KN) | 91.5max |

| Winding and rewinding peed (m/min) | 0~26 | |

| Rope diameter (mm) | ø21.5 | |

| Drum capacity (m) | 550 | |

| Hydraulic winch (for uplift, drilling pipe, pile) | Pulling force of single rope (KN) | 68max |

| Winding and rewinding peed (m/min) | 0~32 | |

| Rope diameter (mm) | ø20 | |

| Drum capacity (m) | 265 | |

| Swing angle (°) | ±10 | |

| Transverse travel | Travel speed (m/min) | < 4.5 |

| Travel step (mm) | 3100 | |

| Vertical travel | Travel speed (m/min) | < 2.7 |

| Travel step (mm) | 800 | |

| Uplift of the track | Speed (m/min) | < 0.55 |

| Height (mm) | +450~-450 | |

| Distance between tracks | Working (mm) | 9100 |

| Travelling (mm) | 4800 | |

| Distance between pulleys in track | Working (mm) | 4800 |

| Travelling (mm) | 5000 | |

| Transverse-moving track | Length (mm) | 9500 |

| Width (mm) | 1200 | |

| Vertical-moving track | Length (mm) | 6900 |

| Width (mm) | 1700 | |

| Connection between outrigger beam and platform | Pin rotary, cylinder expanding | |

| Average ground pressure (MPA) | ≤0.1 | |

| Motor power (kw) | 45 | |

| Hydraulic crowded system (MPA) | 25/20 | |

| Hydraulic crowded system operation | Manual & electric control | |

| Total weight of piling rig (T) | ≈130 | |

Note: Specifications are subjected to change without prior notice.

Leader length can be extended to 42m according to special requirement.

Application

MEXICAN PROJECT Product: D100&JB160A / TAIYUAN PROJECT Product: ZLD180 &JB160A / PHILIPPINE PROJECT Product: D138&JB160A / SHANGHAI EXPO SITE Product: ZLD220 & JB160A / MALAYSIA PROJECT Product: ZLD180+JB160A

Service

1. FREE-CALL CENTER SERVICE

We provide free-call center service for 24hours. For further information of SEMW products or after-sale service, please call us at+0086-21-4008881749. We will provide information or solutions you need.

2. CONSULTANCY & SOLUTIONS

Our professional team offers free consulting services according to different job sites, soil conditions and your requirements.

3. TESTING & TRAINING

SEMW is committed to free guidance of installation and testing, to make sure that you can make proper operations.

We will offer training on site if it is necessary, to make sure you know the correct way for maintenance, analysis and debugging of the malfunctions.

4. MAINTENANCE & REPAIR

We have offices in many places in China, easy for maintenance.

Sufficient supplies for spare parts and wearing parts.

Our service team has a wide range of professional experience on any size project large or small. They provide best solutions with quick response.

5. CUSTOMERS & CONNECTIONS

After-sale customer file was set up for better understanding your need and feedback.

More services are provided, such as, sending info of new released products, latest technology. We also provide special offer for you.

THE GLOBAL MARKETING NETWORK

Diesel Hammers are the key product of SEMW. They have achieved a good reputation domestically and overseas. SEMW diesel hammers are exported in a large quantity to Europe, Russia, Southeast Asia, North America, South America, and Africa.

한국어

한국어